Jensen Mixers Series 600HT Asphalt Mixer

Designed Specifically for High Temperature Asphalt Applications

The HT series was intended specifically for asphalt service and featured a forward seal arrangement within the body cavity to preclude asphalt penetration where it could set up during tank downtime.

The oil reservoir and circulation system was designed to put a positive pressure on the loop sufficient to overcome the tank head.

This design was obsoleted some years back in favor of the Jensen Series 500 Mixers which eliminated the forward body and also permitted the use of either a stuffing box arrangement or a steam purged or thermal syphon double mechanical seal. The Series 500 Mixers have been very well received and are in widespread use. Jensen continues to support the obsolete Series 600HT with a complete array of replacement parts.

Maximum horse power 75 and gear driven. In every horsepower range it offers superior life and load figures, unmatched ease of maintenance and outstanding mixing efficiency. Jensen standard materials offer optimum performance in any hydrocarbon application.

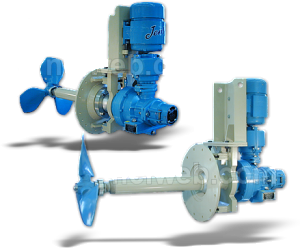

Jensen Mixers hang directly on your tank’s manway (only). No need for additional equipment such as tie rods and/or a base (unlike our competition). Jensen Mixers’ short shaft design (which is supported both at the front and rear of the shaft) provides for vibration-free service. This ensures a long life to the mixer’s mechanical seal, gearbox, bearings etc. Only Jensen Mixer provides you with a (mixer) propeller custom pitched for your application. Jensen Mixer has well over 15,000 mixers in service today. Go with Jensen and get unequaled experience, time proven designs that out-perform and out-last all of our competitors.

- Shaft and wear sleeve – Stainless Steel (Option for 316SS)

- Lock ring, lock bushing, & seal housing – 316 Stainless Steel

- Drive Yoke – Aluminum Bronze

- Propeller & Body – Cast Carbon Steel (Option for 316SS)

- Gearbox – 356-T6 heat treated Aluminum Alloy

- O Rings – Viton “A”, Buna “N” & Teflon encapsulated Viton

The Jensen Series 600 Mixer is supported entirely by the tank manway or nozzle. No tie rods, bases or other external supports are used. Lightweight and low overhang design are the keys to this money saving feature.

Support for the propeller shaft is provided by the main thrust bearing at the outboard end of the mixer and by the shaft end bearing close to the tank shutoff device. With this long bearing span, any possibility of shaft whip is virtually eliminated. All moving parts are completely enclosed by protective covers.

Innovative Coupling Design

The design simplicity of the Jensen Type FT Non-Lubricated Coupling guarantees maximum life even under the most severe conditions. The tough, multi-ply nylon and rubber flexible element permits angular and parallel misalignment far in excess of other couplings. Steel clamp rings secure the element to the hubs and provide a protective enclosure. Complete coupling covers (standard on every JENSEN Mixer) afford further protection. Removal of the driver, gearbox or flexible element can be accomplished without moving hubs on their shafts. The lower coupling hub forms a protective cover for the pinion assembly.

Efficient Propeller Design

The exclusive Jensen Pitch-Adjusted propeller is a highly efficient, three blade, marine type propeller precision set and permanently fixed at our factory to assure superior mixing performance in each individual application.

Durable Seals

The Jensen Mechanical Seal is an integral part of every Series 600 Mixer and is designed for long life at low cost. Materials of construction were especially selected to suite petroleum applications.

Jensen Series 600 Gearbox

The Model 600 gear box typifies the superior design engineering that has gone into every part of the Jensen Series 600 Mixer.

Maximum gear loading is 54% of rated capacity. Bearings have been selected for extremely long life even in continuous, heavy duty service. The lower flexible coupling half provides rain and dirt protection for the upper pinion bearing. Internal air volume has been reduced to eliminate condensate problems in tropical and coastal areas.

Gear case parts are of high strength, 356-T6 heat treated aluminum alloy. The body is of heat resistant steel to assure positive protection against product leakage under conditions of high temperature.

Available Downloads

Request Series 600 Spare Parts

(Type your company name to begin request)