ATEX Certified – Belt Driven – Side Entry Mixer

For Sediment Control and Blending Applications

Jensen Mixers Series 400 are heavy duty, belt driven units designed for long life and trouble-free operation. Jensen Mixers hang directly on your tank’s manway (only). No need for additional equipment such as tie rods and/or a base (unlike our competition). Jensen Mixers’ short shaft design (which is supported both at the front and rear of the shaft) provides for vibration-free service. This ensures a long life to the mixer’s mechanical seal, gearbox, bearings etc. Only Jensen Mixer provides you with a (mixer) propeller custom pitched for your application. Jensen Mixer has well over 15,000 mixers in service today. Go with Jensen and get unequaled experience, time proven designs that out-perform and out-last all of our competitors.

Standard Series 400 Features Include:

- Shaft and wear sleeve – Stainless Steel

- Lock ring, lock bushing, & seal housing – 316 Stainless Steel

- Drive Yoke – 356-T6 Aluminum

- Propeller- Cast Carbon Steel

- O Rings – Viton “A”

Selection of Jensen Mixer Series 400 Mixer:

Defining your requirements and selecting the right mixer to do the job is most important. Jensen offers a mixer specifically tailored to every need.

Mixer applications can be separated into two categories:

- BLENDING – Mixing two or more fluids to obtain a homogeneous blend in a specified time to specific requirements again demands complete top to bottom “turnover”. Select the Jensen Model 400 Fixed-Angle Mixer. more details

- CLEANING – Removing sediment accumulations from tank bottoms. Select the Jensen Model 400-VA Vari-Angle Mixer. more details

In cases where both services are required, the Vari-Angle should be selected.

Jensen process recommendations are fully guaranteed. Jensen mixers are guaranteed against defects for 12 months.

Series 400 Models

| MODEL | 420** | 450 | 480 |

|---|---|---|---|

| HORSEPOWER (MAX.) | 10 | 30 | 60 |

| SHAFT R.P.M. | 433 | 440 | 427 |

| CRITICAL SPEED* | 2,360 RPM | 1,960 RPM | 2,520 RPM |

| HORSEPOWER RANGE | 5-10 | 5-30 | 40-75 |

| TYPES | FIXED-ANGLE | FIXED-ANGLE VARI-ANGLE | FIXED-ANGLE VARI-ANGLE |

| *PROPELLER SHAFT FIRST CRITICAL SPEED | |||

| ** MODEL DISCONTINUED AS OF 2017. SEE MODEL 450 | |||

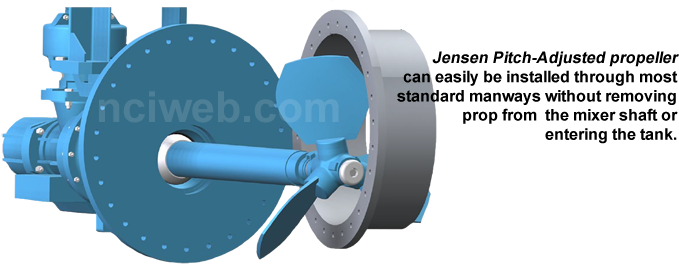

The exclusive Jensen Pitch-Adjusted propeller is a highly efficient, three blade, marine type propeller precision set and permanently fixed at our factory to assure superior mixing performance in each individual application.

- The dependable prop Jensen design relies on 55 years of proven performance.

- The Powerful energy distribution creates predictable flow patterns and efficient temperature uniformity over a large area.

- Low energy requirements reduces overall costs

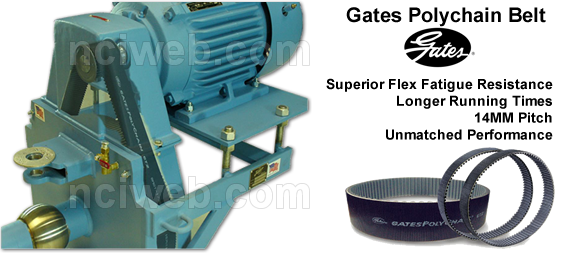

The Jensen Mechanical Seal is an integral part of every Series 400 Mixer and is designed for long life at low cost. Materials of construction were especially selected to suite petroleum applications.

- Long lasting design with options available

- Standard Carbon vs. NiResist or SiC

- TC vs. SiC for more abrasive surfaces

- Tungsten Carbide inner tube seal provides dependable low maintenance operation

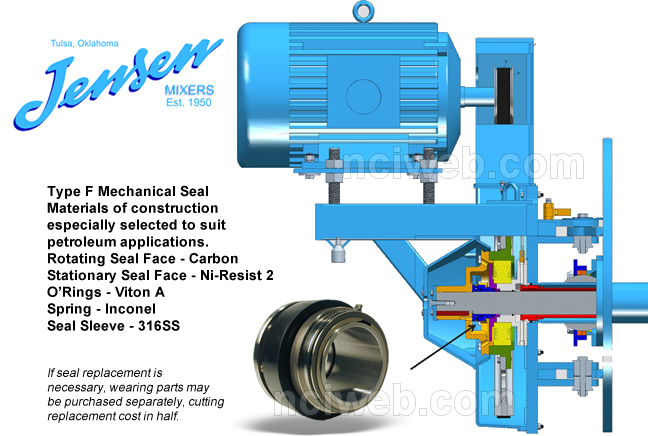

Introducing Jensen’s Sentry Notification System. Achieve a better level of compliance on new or existing Jensen 450 and 480 mixers with the leak prevention system that detects leaks and notifies you before they affect the environment.

HOW IT WORKS: The Sentry system consists of an externally-mounted lube pod that connects to the fluid-filled chamber surrounding the mixer’s mechanical seal. In the event of a mechanical seal failure, the gravity-lubricated system detects and holds maximum tank head pressure safely and reliably until it can be attended to by a technician – thus preventing tank contents from leaking onto the ground. The system can be fitted with remote alert systems to speed up the notification process.

ADVANTAGES: Comes standard on all new Jensen 450 and 480 mixers OR can be retrofitted to existing units (retrofits are completed at our manufacturing facility)

- Environmentally-safe system

- Does not require a power source

- Compatible with third-party sensors and detection systems

- Low maintenance

- Engineered and developed by Jensen engineers to work with Jensen products

- 12 month limited warranty

Available Downloads

- Series 400 Catalog

- Series 400 IOM Manual

- Series 400 Parts Drawing

- Series 400 Seal Containment Drawing